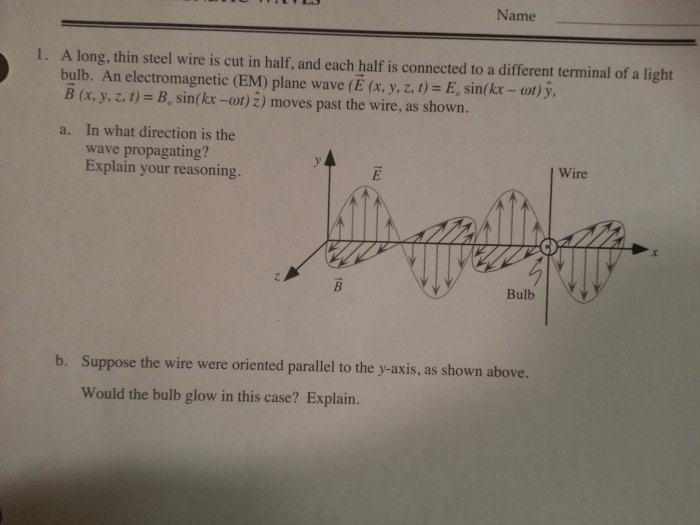

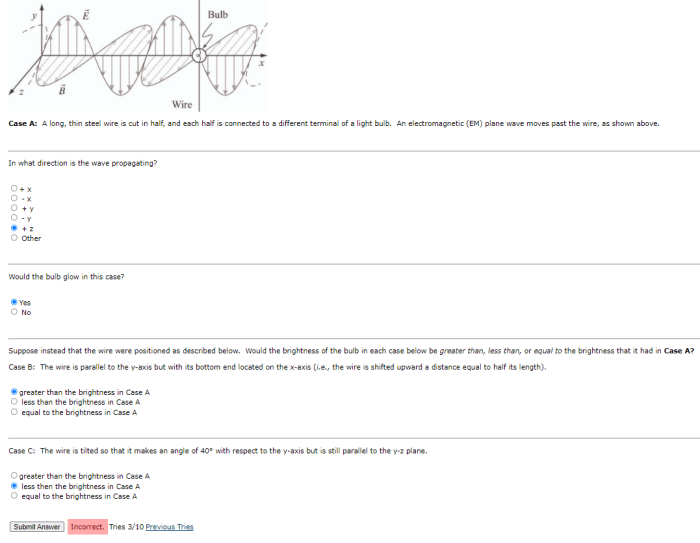

As a long thin steel wire is cut in half, it unveils a captivating exploration of material properties, cutting techniques, and practical applications. This discussion delves into the fascinating world of steel wire, its inherent characteristics, and the consequences of its division, providing a comprehensive understanding of this versatile material.

Steel wire, renowned for its tensile strength and elasticity, exhibits remarkable properties that stem from its unique composition and cross-sectional shape. Its flexibility and rigidity are intricately linked to its diameter, influencing its behavior under various forces. Cutting a long thin steel wire in half necessitates a systematic approach, employing sharp cutting tools and adhering to safety precautions.

The resulting shorter wires inherit distinct properties, opening up a realm of potential applications.

Physical Properties of a Long Thin Steel Wire

Steel wire is a versatile material with a range of physical properties that make it suitable for various applications. Understanding these properties is crucial for selecting the right wire for specific purposes.

Tensile Strength and Elasticity

Tensile strength refers to the ability of a material to resist deformation under tension. Steel wire exhibits high tensile strength, allowing it to withstand significant pulling forces without breaking. Elasticity, on the other hand, is the ability of a material to return to its original shape after deformation.

Steel wire has good elasticity, ensuring it can be stretched and released without permanent deformation.

Cross-Sectional Shape

The cross-sectional shape of a steel wire significantly impacts its properties. Round wires are the most common and offer a balance of strength and flexibility. Square or rectangular wires provide higher strength in specific directions, while flat wires have increased surface area and electrical conductivity.

Wire Diameter

The diameter of a steel wire influences its flexibility and rigidity. Thinner wires are more flexible and can be bent easily, while thicker wires are more rigid and provide greater strength. The diameter also affects the wire’s resistance to bending and twisting.

Cutting the Wire in Half

Cutting a long thin steel wire in half requires careful handling and the use of appropriate tools. Here’s a step-by-step procedure:

- Gather necessary tools: sharp wire cutters, safety glasses, and gloves.

- Secure the wire: Hold the wire firmly in place using a vise or clamps.

- Mark the cutting point: Determine the desired cutting point and mark it with a marker or scribe.

- Align the wire cutters: Position the wire cutters perpendicular to the wire and align the cutting blades with the marked point.

- Apply pressure: Slowly and carefully squeeze the wire cutters to cut through the wire.

- Inspect the cut: Ensure the wire is completely cut and the edges are clean.

Sharp wire cutters are crucial for a clean cut. Dull cutters can crush the wire instead of cutting it, weakening the wire and creating uneven edges. Proper safety precautions, such as wearing safety glasses and gloves, are essential to protect against flying wire fragments and sharp edges.

Consequences of Cutting the Wire

When a long thin steel wire is cut in half, several physical properties of the wire change. These changes include:

- Length:The length of each of the shorter wires is half the length of the original wire.

- Mass:The mass of each of the shorter wires is half the mass of the original wire.

- Resistance:The resistance of each of the shorter wires is double the resistance of the original wire.

- Inductance:The inductance of each of the shorter wires is half the inductance of the original wire.

- Capacitance:The capacitance of each of the shorter wires is half the capacitance of the original wire.

The potential applications of the two shorter wires created by cutting depend on the specific properties of the wire and the desired application. For example, shorter wires with higher resistance could be used as heating elements, while shorter wires with lower resistance could be used as electrical conductors.

The length of the original wire affects the properties of the shorter wires in several ways. For example, the shorter wires will have a higher resistance per unit length than the original wire. This is because the resistance of a wire is directly proportional to its length.

Similarly, the shorter wires will have a lower inductance per unit length than the original wire. This is because the inductance of a wire is inversely proportional to its length.

Applications of Cut Steel Wire

Cut steel wire finds diverse applications in various industries due to its strength, flexibility, and cost-effectiveness.

Construction

Steel wire is widely used in construction for:

Reinforcement in concrete structures

Steel wire mesh or rebars are embedded in concrete to enhance its tensile strength and prevent cracking.

Cable stays for bridges

High-strength steel wires are used as cable stays in suspension bridges, providing support and stability to the deck.

Fencing and security

Steel wire is commonly used for fencing, security gates, and razor wire to deter unauthorized access.

Industrial Applications

In industrial settings, cut steel wire is utilized for:

Wire ropes and cables

Steel wires are twisted or braided together to form wire ropes and cables used in lifting, hoisting, and towing operations.

Spring manufacturing

Steel wire is drawn into various diameters and shapes to create springs for a wide range of applications, such as shock absorption and energy storage.

Musical instruments

Steel wire is used in the strings of musical instruments like guitars, pianos, and violins, producing distinct tones and resonance.

Advantages of Steel Wire, A long thin steel wire is cut in half

High strength and durability

Steel wire exhibits exceptional strength-to-weight ratio and resistance to wear and tear.

Flexibility

Steel wire can be easily bent and shaped, making it suitable for various applications.

Corrosion resistance

Galvanized or coated steel wire provides excellent resistance to corrosion and rust, ensuring longevity.

Cost-effectiveness

Compared to other materials like copper or aluminum, steel wire is relatively inexpensive, making it an economical choice.

Disadvantages of Steel Wire

Susceptibility to magnetic fields

Steel wire is magnetic, which can interfere with sensitive electronic devices.

Brittleness

Steel wire can become brittle under certain conditions, such as extreme cold or fatigue, reducing its flexibility.

Weight

Steel wire can be heavy, limiting its use in applications where weight is a critical factor.

Comparison with Other Materials

Steel wire is often compared to other materials like copper wire, aluminum wire, and synthetic fibers:

Copper wire

Copper wire offers higher conductivity and is less susceptible to magnetic fields, but it is more expensive and less strong than steel wire.

Aluminum wire

Aluminum wire is lightweight and corrosion-resistant, but it is less strong and more brittle than steel wire.

Synthetic fibers

Synthetic fibers like nylon and polyester are lightweight and flexible, but they have lower strength and durability compared to steel wire.

FAQ Compilation: A Long Thin Steel Wire Is Cut In Half

What are the key physical properties of steel wire?

Steel wire exhibits high tensile strength, elasticity, and flexibility, making it resistant to stretching and deformation.

How does the cross-sectional shape of steel wire affect its properties?

The cross-sectional shape influences the wire’s flexibility and rigidity, with circular cross-sections providing greater flexibility and non-circular cross-sections offering increased rigidity.

What safety precautions should be taken when cutting steel wire?

Always wear protective gear, use sharp cutting tools, and secure the wire firmly before cutting to prevent accidents.